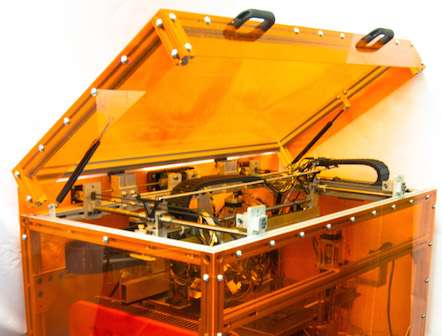

A paper published in ACM Transactions On Graphics by researchers from MIT’s Computer Science and Artificial Intelligence Laboratory has reported the production of a new, super 3D printer which is set to revolutionise the design industry.

The MultiFab has three key advantages over its less-capable predecessors:

1. It can print in up to 10 materials at any one time, unlike traditional 3D printers which have only ever been able to handle three in any one go, opening new realms of manufacturing possibilities.

2. It’s cheap. Well, it’s cheaper. With current 3D printing models coming up at around $250,000 (£160,000), MultiFab costs a meagre $7,000 (£4,430). Despite its complexity, the parts used to build the machine are all off-the-shelf components.

3. It can self-calibrate and self-correct. The team behind the printer gave it ‘machine vision’, meaning that it detects errors in the printing process and corrects them without the need for human intervention, making it more user friendly as well as vastly more efficient. The advancement also means that the objects being printed can be significantly more complex. The machine vision technology allows it to build around and on top of other objects. Circuits and sensors can now be printed as part of the designs, manufacturing a fully finished product with all parts present.

The affordability and accuracy of a development such as the MultiFab suggests that 3D printing could be brought into even wider-usage, extending its function to small businesses and amateur designers, as well as increasing manufacturing time for larger companies.