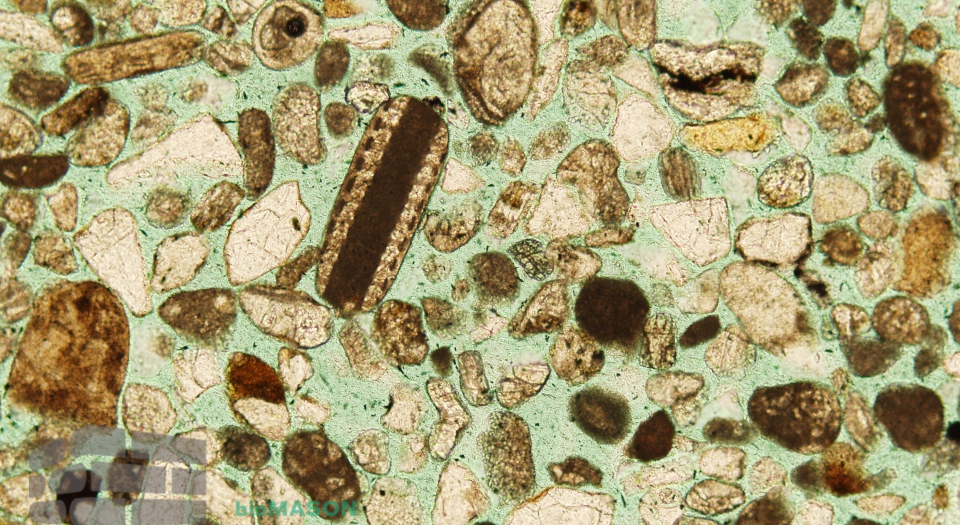

bioMASON has plans to sell their eco-friendly ‘own-grown’ bricks made of a bacteria and sand combination. The sustainable construction project could be sold as early as next year. With the building industry, architects and distributors constantly under pressure to be environmentally friendly the grown bricks could be the latest revolutionary material.

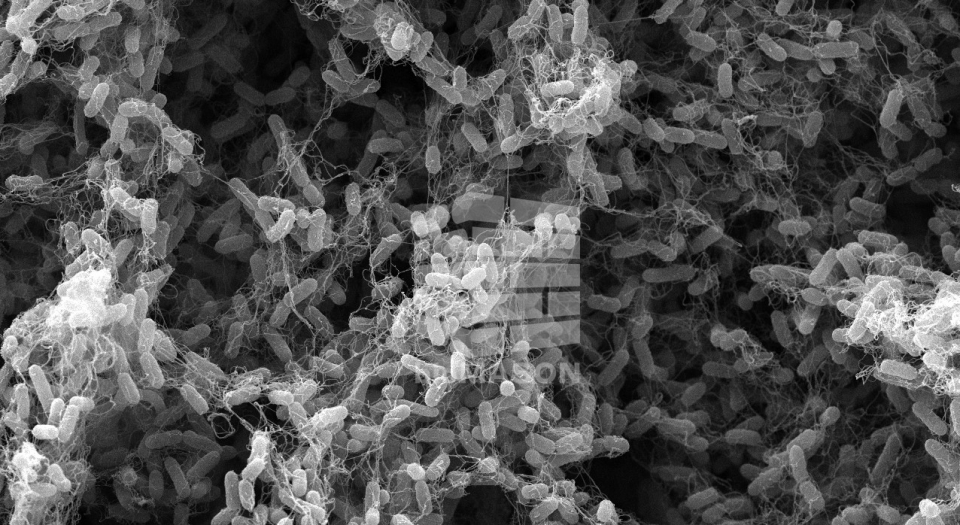

“bioMASON has developed a technology using microorganisms to grow biocement™ based construction materials” – bioMASON

Grown from bacteria and sand opposed to the traditional fired bricks could cut emissions dramatically. Fired bricks take 3-5 days to bake and it is estimated contribute 800 million tons of carbon pollution annually.

In contrast, each bioMASON brick takes 2-3 days to grow, releases no emissions but even claims to absorb pollution which, could be the forefront against climate change. The North-Carolina start-up already has a prototype plant in Durham, NC producing around 1500 bricks a week.

bioMASON was founded in 2012 and since then has been creating innovational green building materials. CEO Ginger Krieg Dosier has been promoting and perfecting zero emission implementation from the beginning as she realises the changes which need to be made.

Around 40% of global emissions comes from the construction industry; bioMASON hopes in the future to drastically reduce this figure.

Find out more, bioMASON