The unprecedented circumstances that put their stamp on 2020 have greatly accelerated the CNC industry’s technological innovations and advancements. Thanks to the increased focus on automation, waste reduction, globalized competition, and the latest emerging technologies, accompanied by the new sense of urgency, 2021 promises a series of exhilarating trends and innovations that will further change the face of the CNC industry.

Besides, as it gets harder and harder to find and retain a decent workforce (operators and programmers), both companies that use in-house CNC machining for the production of specific parts and components, and third-party services that are specialized and offer various CNC services whether it’s CNC milling services, CNC drilling, or CNC turning, are seeking for greater automation and machines with attached robots to keep up with the pace of the market.

Read along to understand better where the CNC industry is headed, and learn more about the five most noteworthy trends that are likely to emerge in 2021 and the foreseeable future.

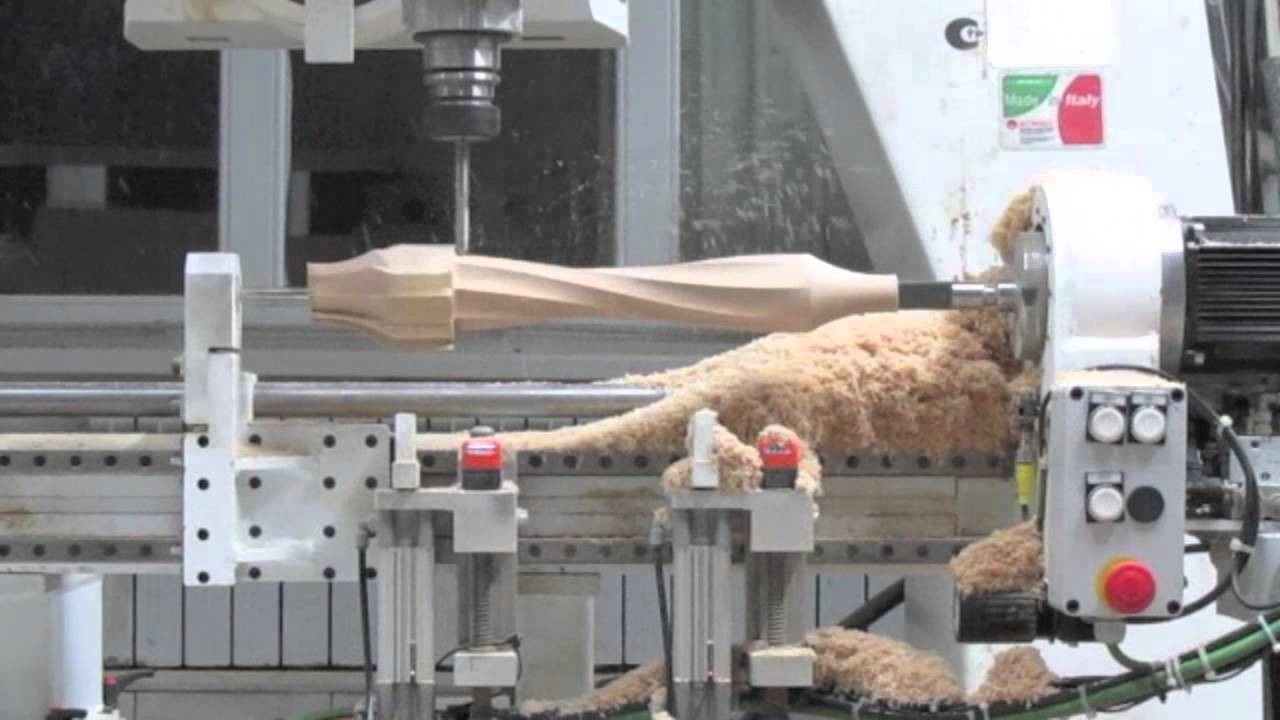

Photo from 3ERP

CNC Machining And The Industrial Internet Of Things

Many industrial facilities have already begun the process of complete automation of the manufacturing process. The Industrial Internet of Things (IIoT) is a digitized automation process that can connect the factory ground and accumulate real-time data about the environment, efficiency, performance, and health of each function within the facility.

While CNC machines are already intelligent enough thanks to their CNC software, by adding a sensor and uniting it to the factory unit via the Internet, CNC machines will produce data on the equipment’s state and the production process’s efficiency, productivity levels, and energy usage. And all of this will directly impact the profitability of the company.

Photo from RAID Conference

Photo from RAID Conference

Besides, by using the IIoT collected data from the CNC machines, the companies will know the exact production rates at any given second. The devices will automatically power down engines when not used to preserve energy costs, recognize when parts are nearing the end of their lifecycle, and assume the exact power demands for manufacturing distinct components.

We anticipate an even higher level of process automation in 2021 as the CNC industry will continue searching for effective methods of increased efficiency and reduced material waste.

6-Axis CNC Machining Will Become The Next Big Thing

We predict that the 6-axis CNC milling machine, which first emerged in late 2019, will become the next big thing in the CNC industry. After all, the more axis there are – the less production time. As it stands, the biggest CNC machining revolution of the next decade might be the 6-axis machining approach.

Multi-axis machining relates to a particular CNC machine’s capacity to move in four or more directions to provide enhanced finishing to the raw material. It uses a milling procedure to remove excess raw material from the machine and create one final product.

At present, most of the CNC machines provide three to five-axis support. It means that the tool can process a product in three dimensions (x, y, and z), while 5-axis machines use a rotating spindle to work with an additional two axis. The 6-axis CNC machine will allow a further rotation around the z-axis, making for speedy cut times.

In the following period, we can expect that more and more genuine manufacturers and third-party CNC shops will turn their attention to 6-axis CNC machines that will prove ideal for high-accuracy production of giant machine parts such as aerospace and automotive components that require the highest precision possible. The 6-axis CNC machines will definitely become an industry staple in the upcoming period.

Photo from cnc.com

Photo from cnc.com

Numerous CAM Software Upgrades

Computer-Aided Manufacturing (CAM) Software is an essential component of CNC machining, blending Computer-Aided Design (CAD) designs into a virtual system. CAM software determines the optimal settings and sequence for the machine to take to minimize the prospect of error or sub-optimal parts.

One of the newest traits that CAM software has included as a standard is collision disclosure. As the machines become more intricate and introduced with more axis, the margin for error and collision is more critical than ever.

This is where numerous CAM software upgrades are expected to kick in. These software advancements will prove highly beneficial for a newer CNC machining workforce as they should yet develop the skills to anticipate such failures and setbacks.

Thanks to the new CAM software versions, these employees will work the CNC equipment worry-free by merely letting the software estimate the machine’s given operation instead.

Expect tons of software progressions and improvements in the next couple of years, as this is undeviatingly connected to how skilled personnel will become more critical than ever. Highly experienced CNC programmers, software developers, and operators will have a considerable amount of work in the upcoming period.

Manufacturing As A Service Will Keep Gaining Popularity

Manufacturing as a service (MaaS) made its way into the CNC industry over the last few years, but expect for it to obtain broader acceptance as we advance in the foreseeable future. MaaS utilizes networked resources to achieve manufacturing tasks, as CNC machines are placed in a central location, and the costs of operation, maintenance, and repairs are equally spread among its subscribers.

Manufacturing as a service option provides companies added productivity, flexibility, agility, and cost savings through reduced labor expenses. As the fallout from the Covid-19 pandemic persists, expect for companies to explore an expanding network of supply chains through MaaS.

Highly Skilled Personnel Will Become Vital Part For Every Successful Company In The CNC Industry

More and more people panic that automation and technology are taking away people’s jobs from production facilities, but it’s quite far from reality. There’s no disputing that machines have significantly decreased employment in manufacturing enterprises.

Still, there’s a tremendous demand for tech-smart staff who can keep up with the most advanced CNC machining trends and streamline the manufacturing process.

Photo from Fortune

Photo from Fortune

Proficient and skillful manufacturing machinists and specialists will become valuable assets to any production company. They will become a decisive factor for the company’s growth in the next ten years.

Besides owning the latest manufacturing technology, the organizations will also need highly-skilled employees to use them efficiently, which will never change.

Final Words

Regardless of 2020’s unanticipated market interruptions, CNC manufacturing continues to be an essential and booming industry. To be more flexible and adaptable in the face of a future crisis, businesses worldwide must turn toward automated manufacturing solutions like the IIoT, technological advancements like the 6-axis CNC tooling, use superior software, utilize third-party CNC manufacturing solutions, and invest in their employees’ education to ensure wise stewardship over their products and resources. Expect more advancements in CNC machinery to lead the way over 2021 and beyond.

Photo from Thomasnet

Photo from Thomasnet